Introduction

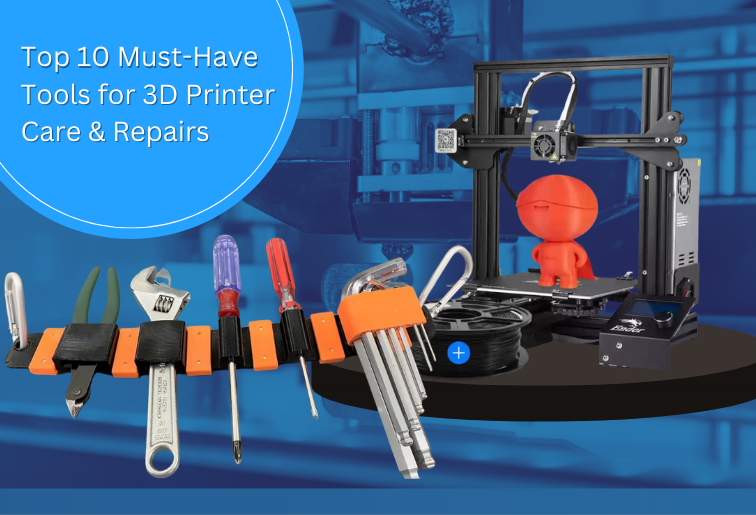

A 3D printer is an incredible tool that brings creativity and innovation to life, but like any machine, it requires regular maintenance to function properly. Without proper care, issues such as clogged nozzles, misaligned beds, and extruder failures can arise, leading to wasted filament, poor print quality, and even damage to the printer. By using the best tools for 3D printer maintenance, you can ensure smooth operation, extend your printer’s lifespan, and achieve consistently high-quality prints.

In this guide, we’ll explore the essential tools you need for effective maintenance and repairs.

1. Nozzle Cleaning Kit

Nozzle clogging is a common issue that affects print quality and filament flow. A nozzle cleaning kit typically includes fine needles, wire brushes, and drill bits designed to clear out filament residue from the nozzle. Using these tools regularly prevents blockages, ensuring smooth extrusion and reducing the chances of under-extrusion or print failures.

For best results, heat the nozzle slightly before cleaning to soften residual filament, making it easier to remove. Additionally, using high-quality filament reduces the likelihood of clogs in the first place.

2. Allen Wrenches & Hex Keys

Most 3D printers use hex screws to secure various components, such as the extruder assembly, frame, and bed leveling knobs. A set of Allen wrenches and hex keys is essential for adjusting or replacing these parts.

Over time, vibrations from printing can loosen screws, affecting print precision. Regularly checking and tightening these screws with the right-sized hex key will keep your printer stable and functioning correctly. Ensure you have both metric and imperial sizes, as some printers use different measurements.

3. Digital Calipers

Precision is crucial in 3D printing, and digital calipers are invaluable for measuring filament diameter, print dimensions, and component tolerances. Filament thickness can vary slightly between brands, and even small differences can affect extrusion rates.

Using digital calipers, you can measure the filament and input the exact diameter into your slicer settings, leading to better print accuracy. They’re also useful for measuring printed parts to ensure they meet design specifications and fit properly in assemblies.

4. Spatula & Print Removal Tool

A spatula or scraper is necessary for safely removing finished prints from the bed without damaging the surface. Stuck prints can be difficult to remove, and forcing them off can damage the print bed or the model itself.

A thin, flexible metal spatula works well for getting underneath prints, while a plastic scraper is ideal for more delicate surfaces like glass beds or magnetic sheets. Some users prefer a razor-blade scraper for extra precision, but caution is needed to avoid scratching the print surface.

5. Build Surface Adhesives

A successful 3D print starts with strong first-layer adhesion. Various build surface adhesives, such as PEI sheets, Kapton tape, glue sticks, or hairspray, can improve adhesion and prevent warping.

Different filaments require different bed surfaces:

- PLA sticks well to blue painter’s tape or a PEI sheet.

- ABS benefits from a heated bed with Kapton tape or a thin layer of ABS slurry.

- PETG adheres well to glass beds with a light application of glue stick to prevent excessive sticking.

Applying the right adhesive ensures better first-layer bonding and reduces failed prints due to detachment.

6. Filament Cutter & Pliers

A sharp filament cutter is essential for cleanly cutting filament before loading it into the extruder. Jagged or uneven filament ends can cause feeding issues and extruder jams.

Additionally, needle-nose pliers help with removing support structures, clearing extruder jams, and cleaning up print imperfections. A pair of flush cutters is also handy for trimming filament and supports with precision.

7. Lubricants & Grease

A 3D printer has many moving parts, including rails, bearings, and lead screws, which require regular lubrication to operate smoothly. Applying lubricants and grease reduces friction, prevents wear and tear, and extends the life of mechanical components.

- Use PTFE (Teflon) lubricant for linear rails and rods.

- Apply white lithium grease for lead screws and threaded rods.

- Avoid using WD-40 as a long-term lubricant, as it tends to evaporate quickly and may attract dust.

Regular maintenance of these parts ensures quieter operation and more precise movement of the printhead and bed.

8. Bed Leveling Tool

A properly leveled bed is crucial for achieving a strong first layer. Uneven beds can lead to adhesion issues and failed prints. A bed leveling tool, such as a feeler gauge, a business card, or an automatic bed leveling sensor, can help maintain the correct nozzle-to-bed distance.

Many printers feature manual bed leveling, requiring users to adjust knobs while checking nozzle clearance. Auto-bed leveling sensors, like BLTouch, automate this process, making it more accurate and efficient.

9. Screwdriver Set

A screwdriver set is indispensable for making adjustments and repairs to your 3D printer. Different screws secure the power supply, control board, and various mechanical parts, so having a variety of Phillips, flathead, and Torx screwdrivers ensures you can handle any maintenance task.

Invest in a magnetic-tip screwdriver set to make working with small screws easier, preventing them from getting lost inside the printer’s frame or electronics compartment.

10. Compressed Air & Brushes

Dust and filament debris can accumulate in your printer’s cooling fans, extruder gears, and electronic components, potentially leading to overheating or mechanical failures. Regular cleaning with compressed air and small brushes helps keep these areas free from dust and buildup.

- Use compressed air to clean cooling fans, stepper motor drivers, and the power supply unit.

- Soft-bristled brushes work well for gently removing debris from gears and extruder assemblies.

- A small vacuum with a brush attachment can be used for thorough cleaning without spreading dust into sensitive areas.

Final Words

Proper maintenance is the key to a reliable and long-lasting 3D printer. By equipping yourself with the best tools for 3D printer maintenance, you can prevent common issues, improve print quality, and extend the life of your machine. Regular cleaning, lubrication, and calibration ensure consistent performance and minimize downtime.

Whether you are a hobbyist or a professional, having the right maintenance tools will save time and frustration, allowing you to focus on creating high-quality prints without unexpected failures. Take the time to care for your printer, and it will reward you with smooth, precise, and hassle-free 3D printing for years to come. Visit Printer Not Working for more!